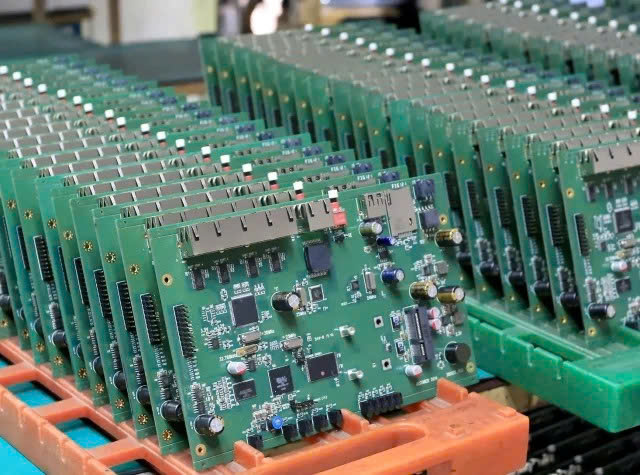

MITR offers professional, end-to-end Printed Circuit Board Assembly (PCBA) solutions tailored to your specific needs. From rapid prototyping to high-volume mass production, we ensure your designs are brought to life with clinical precision and cost-efficiency.

We offer a comprehensive suite of assembly services to meet the diverse technical requirements of our global clients:

SMT (Surface Mount Technology): High-speed automated placement for complex, high-density boards including BGA, QFN, and 01005 components.

THT (Through-Hole Technology): Precision manual and wave soldering for robust components and power electronics.

Mixed Assembly: Seamless integration of SMT and Through-Hole components on single or double-sided boards.

Prototyping & Quick-Turn: Rapid assembly services to accelerate your R&D phase and reduce time-to-market.

Turnkey Solutions: We manage everything—from component sourcing and PCB fabrication to final assembly and testing.

Quality is at the heart of MITR’s operations. Every board undergoes a multi-stage inspection process to ensure zero-defect delivery:

AOI (Automated Optical Inspection): Checking for placement accuracy and solder joint integrity.

X-Ray Inspection: Verifying BGA and hidden solder connections.

ICT (In-Circuit Testing) & FCT (Functional Testing): Ensuring the board performs exactly to your specifications.

Visual Inspection: Final human-led QC for aesthetic and structural perfection.

No. 32D, Alley 77/9, Lane 77 Bui Xuong Trach, Khuong Dinh Ward, Thanh Xuan District, Hanoi, Vietnam

techsale@mitr.com.vn

+84- 942151956

© by MITR, Ltd. All rights reserved. Designed by HTML Codex